MMC is equipped with a comprehensive range of in-house facilities, and we provide an end-to-end manufacturing process that ensures top-notch quality and efficiency. We have an annual capacity of 18000 MT and can cast products up to 6500 KG. Our state-of-the-art equipment and skilled team allow us to handle a diverse array of manufacturing needs and meet your demands with precision and scale.

Our facilities include:

Through our precise sand mixing process, we achieve optimal moulding properties. Our sand testing lab conducts rigorous assessments, enabling us to optimise casting performance. Additionally, our sand reclamation process minimises waste, promoting environmentally responsible manufacturing practices.

We have 2500+ patterns in our in-house library and our CNC pattern making facility delivers precision patterns in a timely manner to ensure accurate casting results.

With our advanced induction furnace, we achieve precise and controlled metal melting for consistent results. We also utilise mechanised riser breaking methods for efficient and safe removal of risers from castings.

Our cutting-edge heat treatment capabilities include a state-of-the-art automatic gas fired heat treatment furnace. With fully automatic units, each precisely controlled by PLC technology, we ensure a controlled and energy-efficient heating environment.

We have integrated advanced automation in our fettling shop using precision manipulators — this reduces manual intervention, enhances worker safety, and ensures consistent, high-quality results.

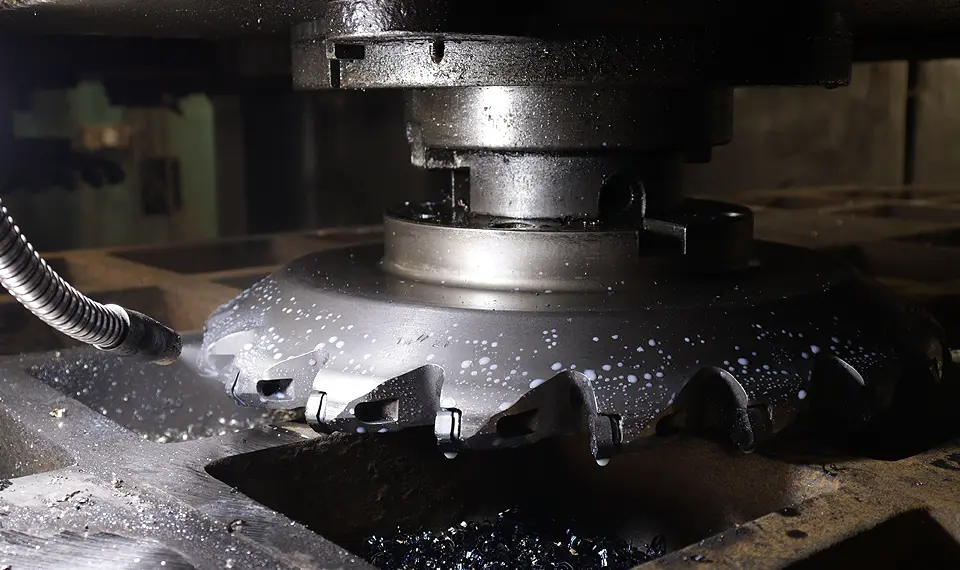

Our well-equipped machine shop features 20+ Vertical Turning Lathes, 15+ Plano Millers, and Special Purpose Machines among others, enabling us to handle diverse machining requirements with our in-house setup.

With over 25 years of expertise in manufacturing wear parts for crushers that deal with the toughest and most abrasive stone/metallic ores, we proudly present our premium Manganese alloy — CRUSHMORETM. This exceptional alloy boasts an ideal blend of Carbon, Manganese, Chromium, and other elements, providing higher initial hardness for superior performance.

Our High Manganese alloy, ASTM A 128 Grade, can be tailored with varying combinations of Manganese (12% to 24%), Chromium (2% to 3%), and life enhancing special additives to suit different stone/ore crushing needs.

At MMC, we take pride in our capabilities, and are committed to continuously investing in

cutting-edge technology and skilled personnel to stay ahead in the manufacturing

industry. We take pride in delivering top-quality stone crusher parts that stand the test of

time, ensuring optimal performance for your crushing needs.

Choose MMC for reliability and excellence in every aspect of stone crushing solutions.